manual calculo para doblar tubos

Tube bending involves shaping metal tubes into precise forms, requiring accurate calculations to achieve desired angles and shapes without compromising material integrity․ Essential for manufacturing, it ensures durability and functionality in applications like automotive and construction․ Proper calculations prevent defects, ensuring safety and efficiency in production processes․

1․1․ Overview of Tube Bending

Tube bending is a manufacturing process that involves shaping metal tubes into specific angles or curves․ It is widely used in industries like automotive, aerospace, and construction to create functional and durable components․ The process requires precise calculations to ensure the tube retains its structural integrity while achieving the desired shape․ Bending can be done manually or through automated systems, depending on the scale and complexity of the project․ Understanding the fundamentals of tube bending is crucial for optimizing production workflows and delivering high-quality results in various applications․

1․2․ Importance of Accurate Calculations

Accurate calculations are crucial in tube bending to ensure precise angles, avoid material deformation, and maintain structural integrity․ Incorrect measurements can lead to defective bends, material wastage, and safety risks․ Proper calculations optimize resource use, reduce production costs, and ensure compliance with design specifications․ They also prevent over- or under-bending, which can compromise the tube’s load-bearing capacity․ Precise calculations are essential for achieving consistent results, especially in industries like automotive and aerospace, where safety and performance are critical; By minimizing errors, accurate calculations enhance efficiency and reliability in tube bending processes․

Types of Tube Bending Methods

Tube bending methods include manual, CNC, and hydraulic techniques, each offering unique advantages for precision, speed, and material compatibility in various industrial applications․

2․1․ Manual Bending

Manual bending is a traditional method involving hand tools to shape tubes into desired forms․ It is a cost-effective and straightforward process, relying on manual force and basic equipment like tube benders or dies․ This technique is often used for small-scale projects or unique bends, requiring precise calculations to achieve accurate results․ While manual bending offers simplicity, it demands skill and experience to avoid material deformation․ Calculations focus on bend radius, springback, and material flexibility to ensure the tube conforms to specifications without cracking or kinking․ Despite its labor-intensive nature, manual bending remains a viable option for customized tube shaping in various industries․

2․2․ CNC Bending

CNC bending uses computer numerical control to precisely shape tubes with high accuracy and consistency․ Unlike manual methods, CNC machines follow pre-programmed instructions, enabling complex geometries and repeatable results․ Advanced tooling ensures tight tolerances, while real-time adjustments optimize the bending process․ CNC bending minimizes human error, increasing efficiency in high-volume production․ It is widely used in automotive, aerospace, and industrial applications, where precision and reliability are critical․ Integrated CAD software allows for seamless design-to-manufacturing workflows, further enhancing productivity and reducing production times․

2․3․ Hydraulic Bending

Hydraulic bending is a precise method of shaping tubes using hydraulic machinery, offering high force application for complex geometries․ It relies on manual calculations to determine factors like bend radius, wall thickness, and material flexibility․ This technique minimizes deformation and ensures accuracy, crucial for applications requiring tight tolerances․ Proper lubrication and tool alignment are essential to prevent damage․ Hydraulic bending is favored in industrial settings for its efficiency and consistency, making it a key component in modern tube bending processes․

Understanding Tube Geometry

Tube geometry involves analyzing diameter, radius, wall thickness, and length to ensure precise bending․ These measurements are crucial for manual calculations, affecting the tube’s flexibility and structural integrity․

3․1․ Tube Diameter and Radius

The tube diameter and radius are critical factors in bending calculations․ The diameter determines the tube’s circumference, while the radius defines its curvature․ Accurate measurements ensure proper fitting and structural integrity․ The bend radius, often larger than the tube radius, prevents kinking or ovality․ For manual calculations, the relationship between the tube’s diameter and the desired bend radius is essential․ Tools like calipers or micrometers measure these dimensions precisely․ Misalignment or incorrect radius can lead to material deformation or failure․ Proper alignment and pressure application are vital for achieving the desired shape without compromising the tube’s integrity or causing unnecessary stress concentrations․

3․2․ Wall Thickness and Its Impact

Wall thickness significantly influences tube bending outcomes, affecting both flexibility and strength․ Thinner walls allow easier bending but risk deformation, while thicker walls provide durability yet require more force․ Proper wall thickness ensures structural integrity, prevents cracking, and maintains dimensional accuracy․ Incorrect measurements can lead to material failure or improper angles, emphasizing the need for precise calculations․ Balancing wall thickness with bending techniques is crucial for achieving desired results in manufacturing applications, ensuring safety, and optimizing performance in final products․

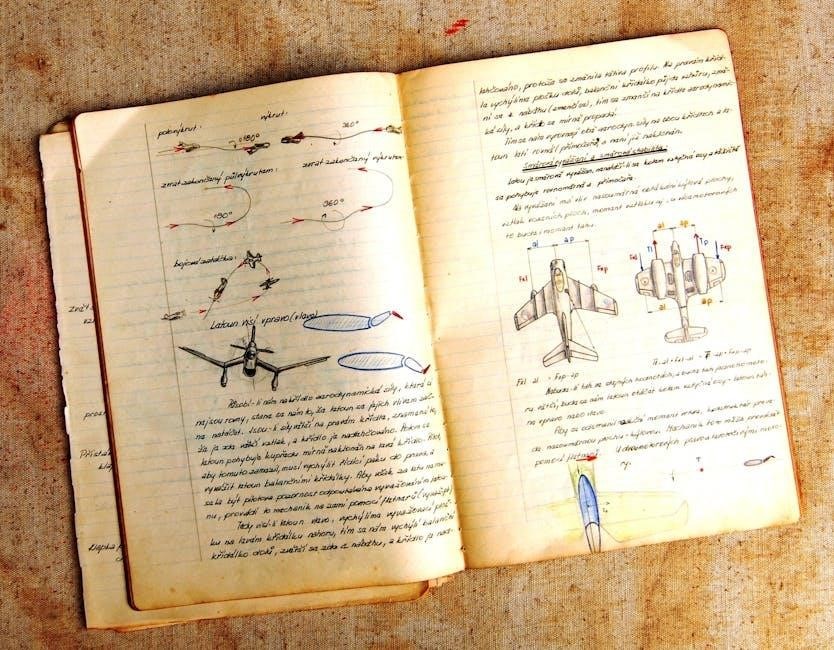

3․3․ Tube Length and Bend Angle

Accurate calculation of tube length and bend angle is crucial for achieving precise bends․ The bend angle determines how sharply the tube will curve, while the tube length ensures the bend fits the application․ Proper measurement tools and mathematical models help predict how the tube will behave during bending․ Errors in these calculations can lead to material deformation or misalignment․ Advanced software often aids in simulating bends, ensuring optimal results․ Skilled professionals use these calculations to minimize waste and achieve the desired shape efficiently, especially in complex geometries․

Material Selection for Tube Bending

Common materials include steel, aluminum, and copper, each offering unique flexibility and strength properties․ Material selection depends on the application, ensuring optimal performance and durability in bent tubes․

4․1․ Common Materials (Steel, Aluminum, Copper)

In tube bending, common materials include Steel, Aluminum, and Copper․ Steel is favored for its high strength and durability, making it ideal for structural applications․ Aluminum is lightweight and corrosion-resistant, suitable for applications where weight reduction is crucial․ Copper, known for its excellent ductility and electrical conductivity, is often used in plumbing and electrical systems․ Each material has unique properties that influence the bending process, such as flexibility and resistance to deformation․ Understanding these characteristics is essential for selecting the appropriate material for specific applications, ensuring optimal results in tube bending projects․ This selection process is vital for achieving desired outcomes in various industries․

4․2․ Material Properties (Flexibility, Strength)

Material properties like flexibility and strength are crucial in tube bending․ Flexibility determines how easily a tube can be bent without deforming, while strength ensures it can withstand bending forces․ Different materials exhibit varying levels of these properties; for instance, steel offers high strength but lower flexibility compared to aluminum or copper․ Understanding these properties helps in selecting the right material for specific applications․ Accurate calculations based on material properties prevent failures and ensure the final product meets design requirements․ Proper material selection enhances both the durability and performance of bent tubes in various industrial applications․

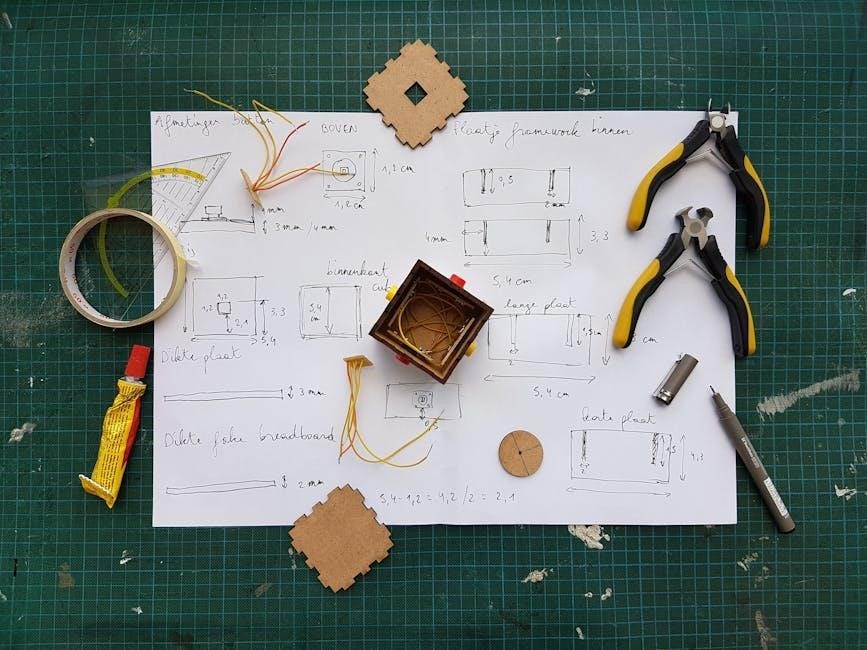

Essential Calculations for Tube Bending

Key calculations include bend radius, springback, and required bending force․ These ensure precise tube shaping, material integrity, and defect prevention in manufacturing processes․

5․1․ Bend Radius Calculation

The bend radius is a critical factor in tube bending, determining the curvature of the tube․ To calculate it manually, measure the tube’s outer diameter and wall thickness․ Use the formula: Bend Radius = Outer Radius ─ Wall Thickness․ Ensure all measurements are in consistent units for accuracy․ This calculation helps achieve the desired angle without damaging the tube, ensuring structural integrity and proper functionality in applications like plumbing or automotive systems․ Proper calculation prevents kinking or flattening, maintaining the tube’s strength and appearance․ Always verify the formula with reliable engineering resources to ensure precision and safety in the bending process․

5․2․ Springback Calculation

Springback is the elastic recovery of a tube after bending, affecting the final geometry․ It depends on material properties like elasticity and hardness․ Thicker walls and harder materials exhibit less springback․ To calculate springback, use the modulus of elasticity (E) and the bend radius (R)․ The formula: Springback (S) = (E * t) / (2 * R * k), where t is wall thickness and k is a material factor․ Accurate springback calculation ensures precise bends, crucial for applications requiring tight tolerances․ Proper compensation enhances product quality and performance in industries like automotive and aerospace․

5․3․ Required Force for Bending

Calculating the required force for bending tubes is crucial to ensure the process is both safe and effective․ The force depends on the tube’s material strength, diameter, wall thickness, and the desired bend radius․ Using formulas derived from material science, engineers can determine the exact pressure needed to achieve the bend without causing structural failure․ This step is essential for optimizing the bending process and preventing defects in the final product․

Factors Influencing Tube Bending

Material properties, machinery precision, and process conditions significantly influence tube bending outcomes, affecting accuracy, efficiency, and final product quality․

6․1․ Lubrication Requirements

Lubrication is crucial in tube bending to reduce friction between the tube and bending tools․ Proper lubrication prevents overheating, extends tool life, and ensures smooth bending operations․ The type of lubricant depends on the material being bent, with water-based or oil-based options commonly used․ Insufficient lubrication can lead to material deformation, increased wear, and potential machinery damage․ Regular application and monitoring of lubricant levels are essential to maintain optimal bending conditions and prevent costly downtime․ Adhering to manufacturer guidelines ensures the right lubrication is applied for specific materials and bending methods․

6․2․ Tooling and Die Selection

Proper tooling and die selection are critical for achieving precise tube bends․ Dies must match the tube’s diameter and desired bend radius, ensuring minimal deformation․ The material’s thickness and flexibility influence die choice, with harder materials requiring more robust tools․ Incorrect dies can lead to wrinkles or fractures․ Regular maintenance of tooling is essential to prevent wear and tear, which can affect bend accuracy․ Advanced machinery often uses interchangeable dies, allowing for versatility in production․ The right tooling enhances efficiency, reduces material waste, and ensures consistent, high-quality bends in various applications․ Proper selection is key to optimizing the bending process and its outcomes․

6․3․ Alignment and Precision

Alignment and precision are critical in tube bending to ensure accurate results․ Proper tool alignment prevents uneven bending, while precise measurements guarantee the desired angles and shapes․ Using laser guides or digital measuring tools enhances accuracy․ Skilled technicians must ensure the tube is centered and securely held to avoid misalignment․ Consistent wall thickness and material properties also influence precision, as variations can lead to irregular bends; Regular machine calibration and die maintenance further ensure reliability․ Achieving high precision reduces material waste and improves the final product’s quality, making it essential for industrial applications․ Proper alignment also enhances safety by minimizing the risk of machine errors․

Tools and Machinery for Tube Bending

Essential tools include manual tube benders, dies, and mandrels, ensuring precise control over tube shaping․ Measurement tools aid in accurate calculations for manual bending processes․

7․1․ Manual Bending Tools

Manual bending tools are essential for precise tube shaping, offering simplicity and cost-effectiveness․ Common tools include tube benders, bending springs, and manual dies․ These tools enable accurate control over the bending process, making them ideal for small-scale projects․ While they require physical effort, manual tools ensure high precision and are often preferred for custom bends․ Safety is crucial, as improper use can lead to injuries․ Proper training and protective gear are recommended․ Despite advancements in automation, manual tools remain versatile and indispensable in various industries, providing a reliable solution for straightforward bending tasks without the need for complex machinery․

7․2; Hydraulic and CNC Machines

Hydraulic and CNC (Computer Numerical Control) machines are advanced tools for precise tube bending, offering superior accuracy and efficiency compared to manual methods․ Hydraulic machines use fluid pressure to bend tubes, while CNC machines rely on automated systems for complex shapes․ Both technologies minimize human error and enable consistent results․ CNC machines, in particular, allow for pre-programmed bending angles and radii, making them ideal for large-scale production․ Modern CNC systems often include simulation software to optimize bending processes and reduce material waste, ensuring high-quality outcomes in industrial applications․

Safety Considerations

Safety in tube bending requires proper protective gear like gloves and goggles․ Regular machine maintenance and operator training are essential to prevent accidents and ensure safe operations․

8․1․ Personal Protective Equipment

When performing manual tube bending calculations and operations, wearing proper personal protective equipment (PPE) is crucial․ Gloves protect hands from cuts and abrasions, while safety glasses or goggles shield eyes from flying debris․ Steel-toe boots prevent foot injuries from heavy tools or falling materials․ In some cases, a face shield may be necessary for added protection․ Ensuring all safety gear is worn correctly minimizes risks and prevents accidents during the bending process․ Proper PPE ensures a safe working environment and protects workers from potential hazards associated with manual bending operations․

8․2․ Machine Safety Precautions

Ensuring machine safety is critical during tube bending operations․ Proper training on equipment operation is essential to prevent accidents․ Regular maintenance of bending machines, including lubrication and alignment checks, helps avoid mechanical failures․ Install safety guardrails and emergency stop buttons to halt operations instantly if needed․ Use appropriate tooling and dies to prevent metal fragments from flying․ Always follow manufacturer guidelines for load limits and operational speeds․ Neglecting safety precautions can lead to equipment damage, injuries, or even fatalities․ Prioritize a safe working environment to protect both operators and machinery, ensuring efficient and reliable tube bending processes․

Case Studies and Examples

Real-world applications include bending copper tubes for plumbing systems, showcasing precise angle achievements through manual calculations, ensuring durability and leak-free connections in residential and industrial settings․

9․1․ Real-World Applications

Manual tube bending calculations are crucial in various industries, including automotive, aerospace, and construction․ In automotive manufacturing, precise bends are essential for fuel lines, brake systems, and exhaust pipes․ Aerospace relies on accurate calculations for creating complex tubing in aircraft fuel systems․ Construction equipment often requires bent tubes for structural frameworks and fluid delivery systems; Additionally, HVAC systems depend on manually calculated bends for ductwork and piping․ These applications highlight the importance of manual calculations in ensuring safety, efficiency, and durability in manufacturing and infrastructure development․

9․2․ Common Mistakes and Solutions

Common mistakes in manual tube bending include using incorrect tools, insufficient lubrication, and mismeasuring the bending radius․ Overbending or underbending can lead to material damage or improper angles․ Solutions involve using tools designed for the specific tube material and diameter․ Proper lubrication reduces friction and prevents tube deformation․ Double-checking measurements ensures accuracy, while applying consistent force avoids overbending․ For complex bends, consulting bending charts or guides is recommended․ Addressing these issues enhances precision and extends tool longevity, ensuring high-quality results in manual tube bending processes․

Manual tube bending calculations are crucial for achieving precise and durable bends, ensuring structural integrity and functionality in various applications․ By understanding geometry, material properties, and bending techniques, professionals can avoid common errors and optimize production processes․ Accurate calculations not only enhance the quality of bent tubes but also reduce material waste and improve safety․ Mastery of these methods is essential for meeting industrial standards and delivering reliable results in manufacturing and engineering projects․ This approach ensures long-term performance and efficiency in tube bending applications across industries․

Further Reading and Resources

For further reading, explore books on tube bending techniques and visit online platforms offering calculators and tutorials․ These resources enhance your understanding and practical skills․

11․1․ Recommended Literature

For in-depth understanding, “Tube Bending Handbook” by [Author] is a comprehensive guide covering calculations and practical applications․ “Manual Calculations for Tube Bending” offers step-by-step formulas and real-world examples․ Online resources like “Tube Bending Guide” provide detailed instructions and interactive tools․ These materials are essential for engineers and fabricators seeking precise methodologies and troubleshooting tips in tube bending projects․

- Tube Bending Handbook: Detailed calculations and practical applications․

- Manual Calculations for Tube Bending: Step-by-step formulas and real examples․

- Tube Bending Guide: Interactive tools for precise bending․

11․2․ Online Tools and Calculators

Various online tools and calculators simplify tube bending calculations, offering precise results for bend radius, springback, and required force․ Software like CAD programs and specialized bending calculators provide detailed simulations and formulas․ Websites such as Engineering ToolBox and Bend-Tech offer free resources for quick computations․ These tools enhance accuracy, save time, and cater to both professionals and DIY enthusiasts․ They often include visual aids and step-by-step guides, making complex calculations more accessible․ By leveraging these resources, users can optimize their bending processes and achieve high-quality results efficiently․